|

上海智尊工业自动化有限公司 |

| |

|

|

|

| 您最信赖的进口备件供应商 |

EBM PAPST

|

依必安派特公司于1963年在德国成立。作为在电机和风机产业领域的技术领导者之一, 依必安派特拥有55家分支机构在世界各地为客户提供专业地风机及电动机的解决方案与服务。 |

|||||||||

Email询价更迅捷: info@zzindustry.net |

|||||||||

|

|||||||||

|

|||||||||

Greater efficiency, less noise, reduced exit losses.

Every medium is only able to absorb a certain amount of heat energy for each degree Kelvin. The possible temperature difference and the amount of heat to be expelled define the cooling air flow required. This air volume has to be delivered by a fan through the heat exchanger under consideration. Because refrigeration technology appliances are usually operated with high operating factors, an economical use of the drive energy input is important, for every additional watt costs money. A suitably configured fan impeller is used to generate a volume flow of air. Here it is important to avoid stripping and back-flows as these create energy losses and unwanted noise. This procedure is state of the art which all manufacturers now more or less command. |

|||||||||

|

|||||||||

Knowing how - the airflow through the AxiTop diffuser To deliver an airflow through a heat exchanger, a sufficient pressure differential is needed to overcome the flow resistance of the exchanger. Normally, the delivered air flows at high speed from the exit side of the fan and is dissipated into the environment. Dissipation means that the kinetic energy of the flow is converted into heat that is no longer technically utilised. The AxiTop diffuser is designed to decelerate the flow, allowing a large proportion of the dynamic kinetic energy to be converted into static pressure. This reverse-conversion boosts the pressure increase of the impeller. If all components are aerodynamically optimised, this allows efficiency to be significantly enhanced, making it possible to reduce the fan speed and thus noise emissions. |

|||||||||

| The AxiTop diffuser offers more options for adaptation | |||||||||

|

In practice, the use of the AxiTop diffuser does not just mean lower energy consumption; it also means greater variance for the user and for the development engineer. The AxiTop diffuser configuration can be optimised for different characteristics, depending on the application concerned. Either a greater air performance is possible with unchanged energy input, or unchanged air performance with lower energy consumption. The AxiTop diffuser can also greatly improve acoustic characteristics. This is especially important in noise-sensitive applications. | ||||||||

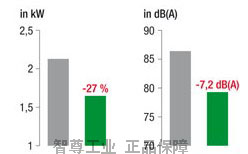

| The scale of possible energy savings - or efficiency enhancement and noise reduction - that can be achieved by fitting an optimal diffuser such as the AxiTop on a conventional heat exchanger is substantial. For example, exchanging a standard guard grille fan for an axial fan with support grille, guard grille and AxiTop diffuser makes savings of up to 27% possible in energy consumption and at the same time up to 7.2 dB(A) less acoustic capacity. |

Operated at the same operating point, energy savings of up to 27% and 7.2 dB(A) less noise development are possible, depending on the application. (measured on size 800 mm) |

||||||||

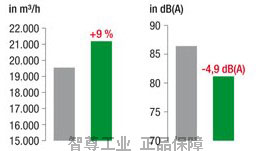

| If, on the other hand, the greater efficiency of the fan with the AxiTop diffuser is utilised, it can provide around 9% more air flow with comparable power consumption, and noise emissions are still 4.9 dB(A) lower. These values can vary according to the operating point and application. Depending on the individual configuration, the optimised efficiency can be used either to reduce power input or to increase air performance. |

Operated at maximum speed, the blower output can be increased by up to 9% and noise development reduced by up to 4.9 dB(A), depending on the application. (measured on size 800 mm) |

||||||||

Ebm-Papst Mulfingen GmbH & Co. KG

| 联系我们 | 常见问题 | Copyright@2009 上海智尊工业自动化有限公司 | ||